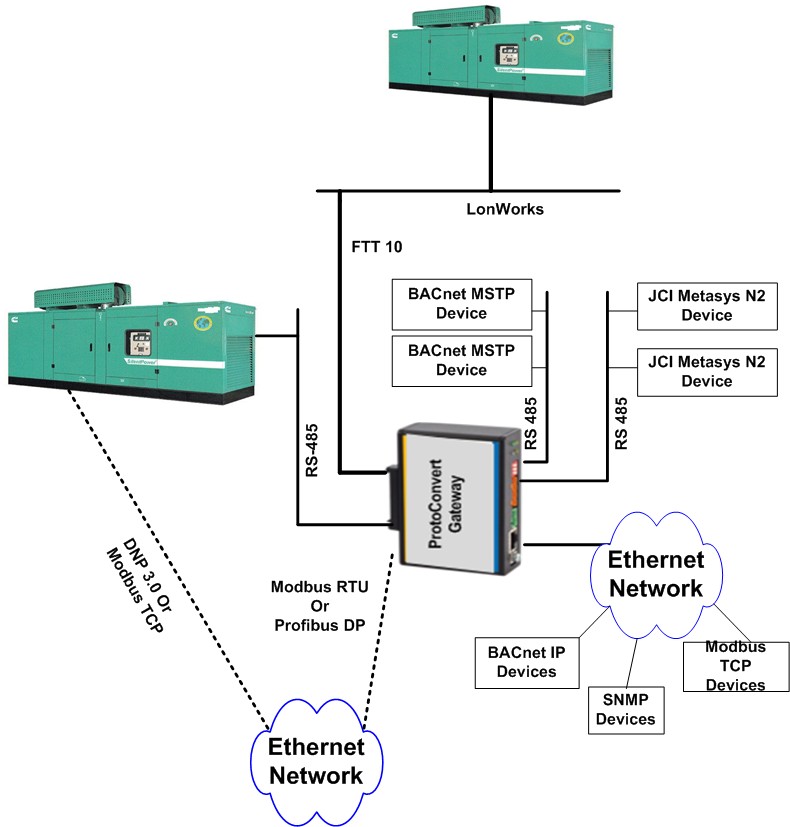

1) ProtoConvert's gateways for integration of Diesel Gensets with your Building Management System:

Our gateways can provide a transparent communication channel so that your Building Management system (BMS) can read data from the Diesel Gensets installed on the site. Typically BMS support Ethernet based protocols like BACnet IP or Modbus TCP while the Diesel Gensets support serial protocols like BACnet MSTP, Modbus RTU or Lonworks. Hence the BMS cannot directly read data from the Gensets and there is a requirement for an intermediate 'protocol' converter.

We can provide a suitable protocol converter for your integration requirement. We will also help you commission our gateway on site and be your integration partner.

2) Remote monitoring of Diesel Gensets and data availability via GSM/GPRS and SMS alerts

Would you like to have access to your Gensets data on the go? Would you like email/SMS alerts based on consumption (or any other parameter)?

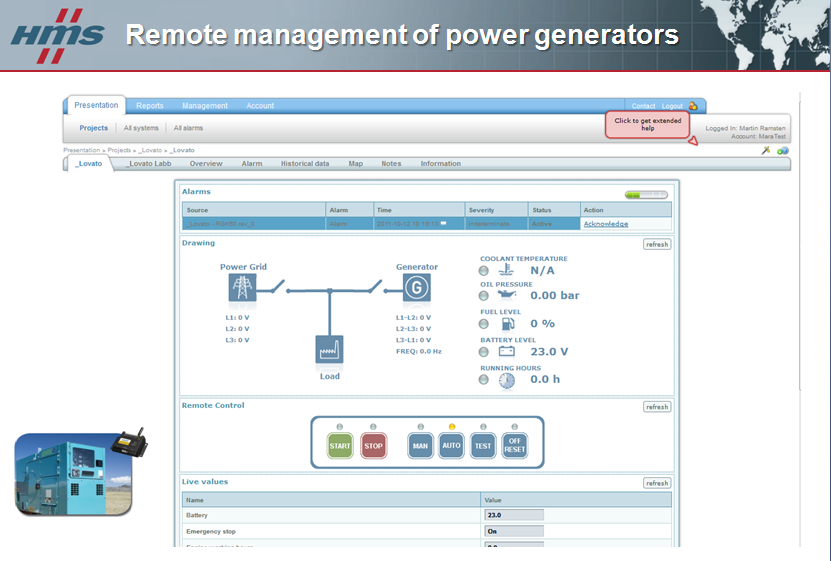

If your answer is yes, then we have the right solutions for you. Using our Netbiter suite of products we can push all the Diesel Gensets data onto our cloud based servers. Hence you can access your site's data from anywhere in the world using any web browser and internet.

Our GSM/GPRS gateways can provide SMS and email alerts based on live readings from the Diesel Gensets installed on site.

Netbiter comes with a screen which acts exactly like a SCADA. Shown below is a glimpse on how your Diesel Gensets model will look.

Some Added advantage of the product is as follows:

- Vendor-independent solution

- Preconfigurations for a wide range of control panels

- Woodward

- DEIF

- Deep Sea Electronics

- Kohler

- Basler

- SDMO

- ComAp

- Dynagen

- FG Wilson

- Etc…

- Quick installation – Less than 15 minutes

- Simple installation – No engineering or programming required on-site.

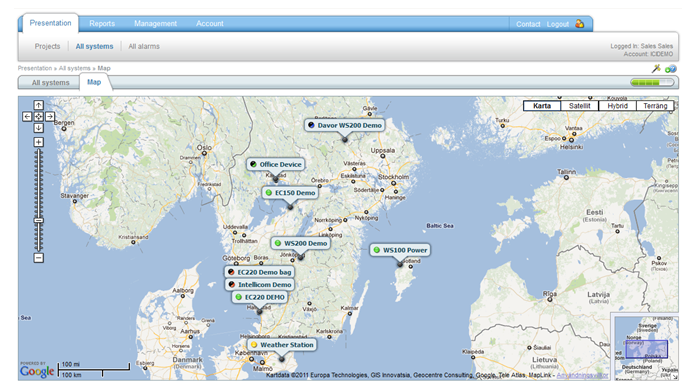

It is also GPS enabled (Optional) which can give you information about the exact location about your Gensets on world map. It can also show an alarm screen on the world map which looks like the one shown below.

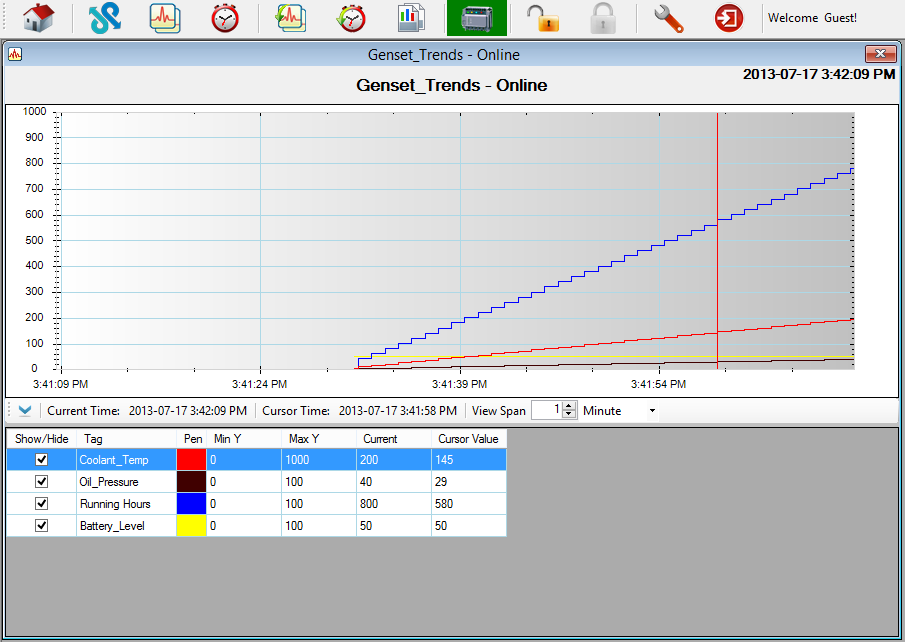

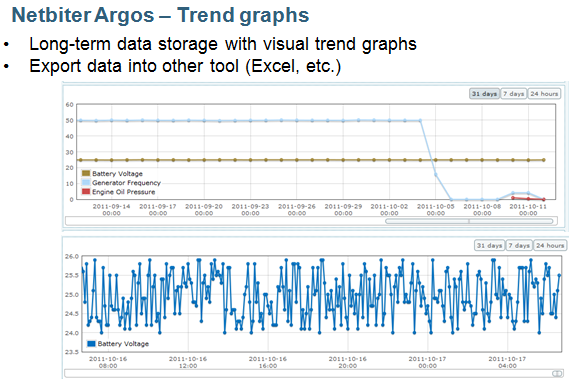

Trending data and storing historical data. Netbiter comes with inbuilt screens for trends and data storage.

3) SCADA/HMI for monitoring and control:

Our Black Diamond SCADA/HMI can provide a single console monitoring and control solution for your requirement. We can display data from all the Diesel Gensets on site on a single console. It would also be possible to store data for future analysis, view trend screens for live data or for historical data and generate reports. Our SCADA can be used for local monitoring purposes.

Trend Screen on the SCADA will look like the following: